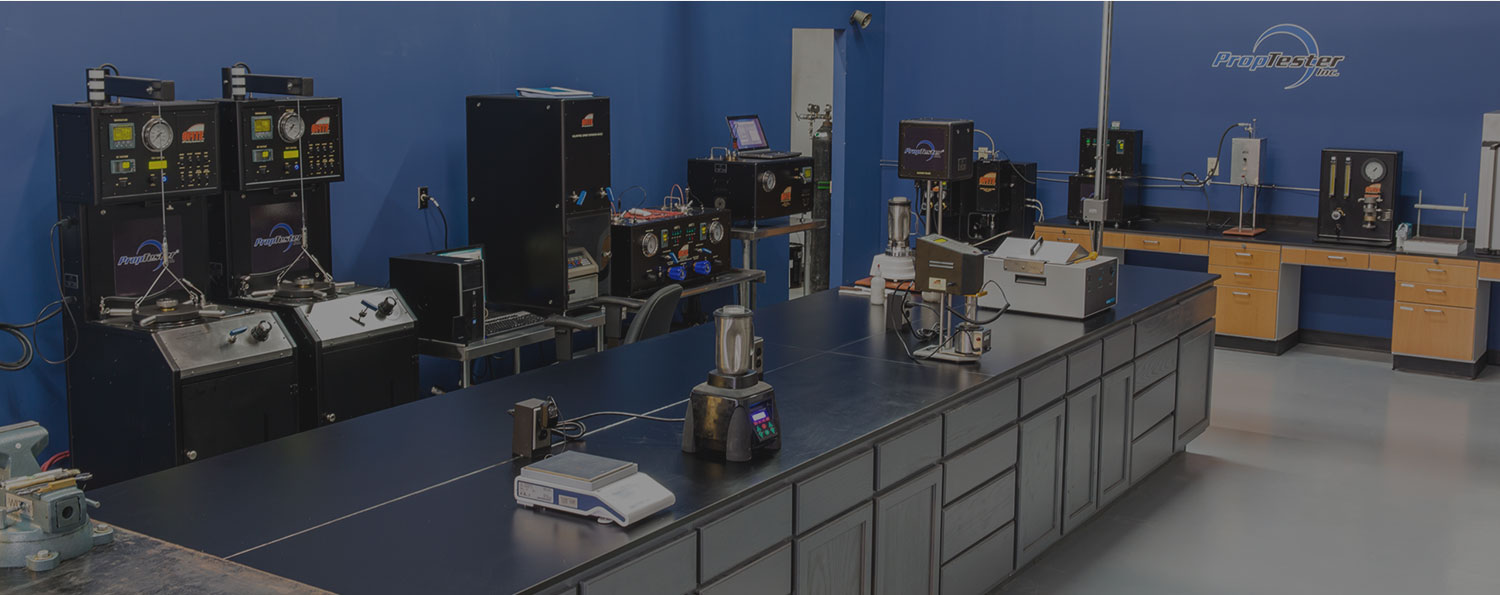

Many properties need to be considered when selecting the right fluids for your well. PropTester provides extensive research and testing capabilities both inside the lab and at the well-site to determine which fracturing fluids are best suited for your specific field application using standard and well-specific procedures. Our expert lab technicians can work side-by-side with clients to validate current fluid systems and also work with companies to create new systems. All data is maintained centrally by PropTester for future comparison or application, as needed.

Guar Testing

PropTester®, Inc. provides in-depth test results on raw and refined guars from across the globe. The demand for guar in the oil industry has risen over the past few years and several new areas have been experimenting with growing guar beans. With this in mind, the quality of the product is very important.

In-depth guar testing includes particle distribution, moisture content, hydration time, cross-link performance, insoluble acid residue, and the measurement of pH.

Regain Conductivity Fluid Testing

Fracturing fluid can reduce proppant pack conductivity by 90% as it is being placed in the formation. Regain Conductivity is performed measure the impact of the fluids on the proppant pack. This test can be customized to well specifics up to 20,000 psi and 500F. Set up includes a baseline and can test up to three other samples at once. Flow Back and Beta Factor testing can be added upon request.

Fluid Rheology

Pre-job fluid rheology profiles and breaker schedules can be obtained with recommended formulations using a high pressure / high temperature Rehometer. Customize your tests to suit your needs. Shear rates from 1 to 1000 sec-1, up to 500F and 2000 psi. All data is maintained centrally by PropTester®, Inc. for future comparison or application, as needed.

Other tests include Fluid Compatibility testing, Friction Flow Loop testing and Barite Testing. To directly contact our fluids laboratory or request a quote, click here.

Fracture Fluids Testing and Oversight

PropTester fluid specialists are on location (onshore or offshore) prior to the stimulation treatment to ensure quality. Tasks include identifying chemical additives, auditing chemical & base fluid inventories, evaluating chemical compatibilities, verifying cross-link times, and calibrating chemical feed pumps. The job design, a pre-frac material balance, and treatment schedule are reviewed with service company personnel and the operator representative. Chemical inventories are documented during each stage and the final mass balance is calculated. Proppant transportation & delivery records are also recorded as part of the fluid service.

Polymer Injection

Ensure proper mixing and application of your polymer injection treatment at the well-site. Reservoir conformance sometimes employs a polymer injection process to block high permeability fractures and channels in both injection well and producing well applications. A synthetic polymer (e.g. polyacrylamide) which is cross-linked can provide an effective means to modify a water injection profile and/or improve oil recovery. However, a successful gel treatment is based on effective quality control (QC) practices to ensure proper mixing and performance. Polymer injection QC oversight by PropTester®, Inc. includes the following:

Pre-job review of treatment objectives, gel technology, available equipment (e.g. mixing tanks, weigh scales) & rig-up procedures

- Pre-job analysis & compatibility testing of mixing water (e.g. brine or sea water)

- Pre-job preparation & grading of gel samples with chemicals & water to be employed

- Observation of treatment mixing procedures & metering during the job

- Sampling, evaluation, grading, & comparison of in-line samples retrieved during the job

- Physical inventories (Final – Initial)

- Material balance calculations

- Photographs